- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

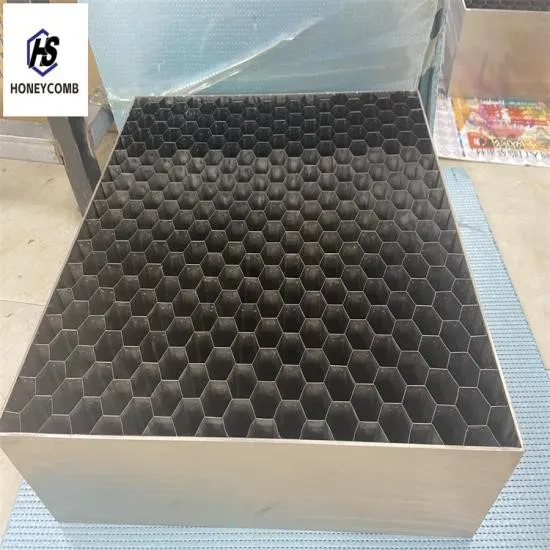

Honeycomb Stainless Steel Air Flow Straightener | Hengshi Precision Machinery

Product Introduction

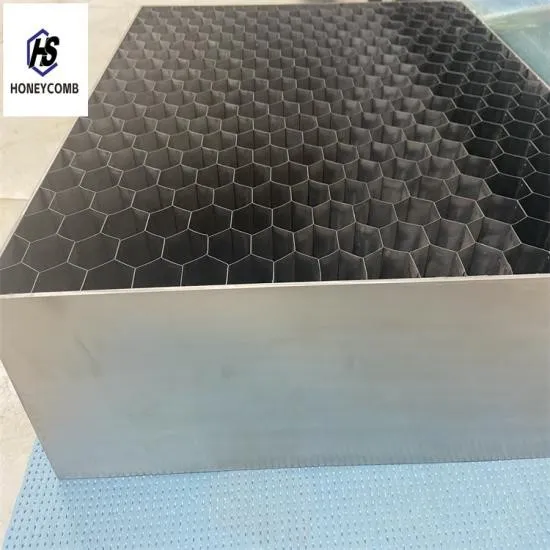

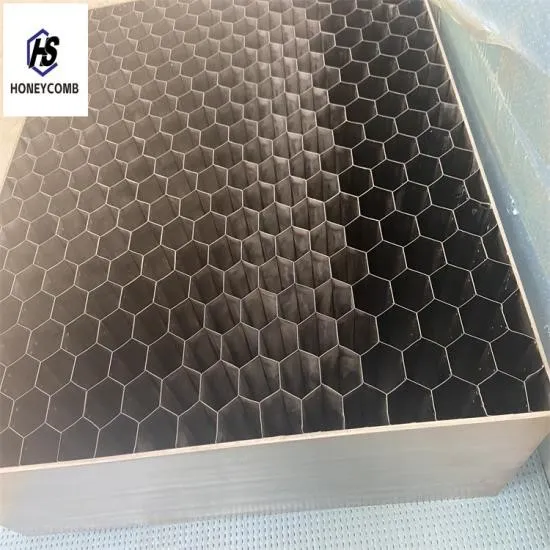

The Honeycomb Stainless Steel Air Flow Straightener is a critical component in aerodynamic testing and flow control systems. This innovative device utilizes a structured honeycomb matrix to transform turbulent airflow into laminar flow, ensuring precise measurement and analysis in various industrial applications. Its robust design and advanced material composition make it a preferred choice for aerospace, automotive, and marine engineering sectors.

As highlighted in the product page, the straightener's unique geometry features thin cell walls that create an array of straight passageways. This design achieves a maximum open area of 95-99%, significantly reducing pressure drop and turbulence. The technology has been successfully applied in fields ranging from aircraft design to high-speed train testing, as noted by the National Institute of Standards and Technology (NIST) in its research on fluid dynamics.

Key Features and Advantages

- High Shielding Effectiveness: The stainless steel construction provides exceptional electromagnetic interference (EMI) shielding, crucial for sensitive testing environments.

- Corrosion Resistance: Available in materials like 304 and 316L stainless steel, ensuring durability in harsh environments.

- Optimized Airflow Control: The honeycomb structure minimizes turbulence, enhancing the accuracy of aerodynamic measurements.

- Customizable Design: Tailored to specific applications with options for thickness, core size, and surface treatments.

- Compliance Standards: Certified under ISO9001 and RoHS, reflecting the company's commitment to quality and environmental responsibility.

Technical Specifications

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30mm (customizable) |

| Thickness | Customized |

| Shape | Customizable |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating |

| Package | Wooden cases or as required |

| Certifications | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Applications | EMI shielding vent, flow straightener, railways, marine, aviation & aerospace, wind energy, defense, gas seals, communications, medical |

Applications in Modern Engineering

The honeycomb air flow straightener plays a vital role in wind tunnel testing, which is essential for studying aerodynamic effects. As explained by NIST in its research on fluid dynamics, wind tunnels simulate real-world airflow conditions to test the performance of vehicles, structures, and equipment. The straightener's ability to stabilize airflow ensures accurate data collection, which is critical for design optimization.

Key applications include:

- Aerospace: Testing aircraft, missiles, and spacecraft for aerodynamic efficiency and structural integrity.

- Automotive: Evaluating vehicle aerodynamics to improve fuel efficiency and stability.

- Marine: Assessing hull designs and propulsion systems for ships and submarines.

- Renewable Energy: Optimizing wind turbine blade performance through airflow analysis.

- Defense: Testing military equipment for resistance to extreme environmental conditions.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

As a leading manufacturer in the field, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. specializes in producing high-quality shielding products, including ventilation panels, steel honeycomb cores, honeycomb air flow straighteners, and honeycomb seals. The company's commitment to innovation and precision has established it as a trusted partner for industries requiring advanced airflow control solutions.

With a focus on EMI shielding and corrosion resistance, Hengshi's products are designed to meet stringent industry standards. The company's state-of-the-art manufacturing processes, including spot welding and vacuum brazing, ensure the durability and performance of its offerings. As noted in the product page, Hengshi's certifications (ISO9001, RoHS) reflect its dedication to quality and sustainability.

Why Choose Hengshi's Honeycomb Solutions?

Hengshi's honeycomb air flow straightener offers several advantages over traditional flow control systems:

- Superior Performance: The high open area (95-99%) minimizes pressure loss while maintaining laminar flow.

- Customization: Tailored to specific project requirements, ensuring optimal integration into existing systems.

- Longevity: Corrosion-resistant materials ensure extended service life in demanding environments.

- Compliance: Adherence to international standards like ISO9001 and RoHS guarantees quality and safety.

According to NIST's research on aerodynamic testing, the accuracy of flow measurements is directly linked to the quality of flow straighteners. Hengshi's products exemplify this principle, providing reliable performance in critical applications.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener from Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. represents the pinnacle of engineering excellence in airflow control. With its advanced design, customizable features, and compliance with global standards, this product is indispensable for industries relying on precise aerodynamic testing and flow management. Whether in aerospace, automotive, or renewable energy sectors, Hengshi's solutions deliver the reliability and performance needed to drive innovation.

References

National Institute of Standards and Technology (NIST). (n.d.). Fluid Dynamics Research. Retrieved from https://www.nist.gov/

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025