- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

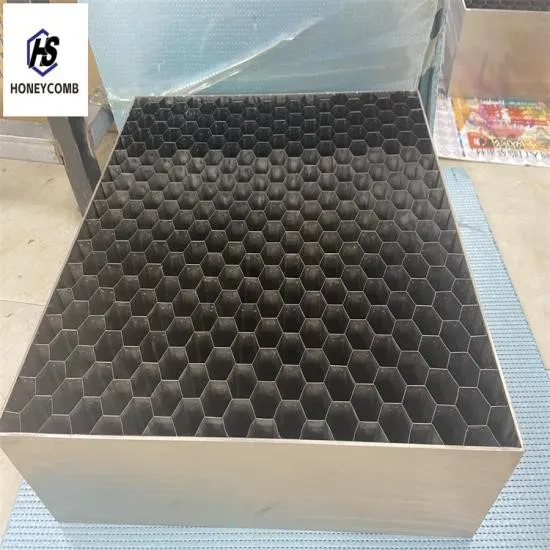

Honeycomb Stainless Steel Air Flow Straightener - Precision Airflow Stabilization & Aerodynamic Testing | Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Honeycomb Stainless Steel Air Flow Straightener has emerged as a critical component in modern aerodynamic research and industrial applications. Designed to stabilize airflow and reduce turbulence, this advanced engineering solution is widely used in wind tunnels, aerospace testing, and environmental control systems. Manufactured by Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd., the product combines cutting-edge materials with precise design to meet the demands of high-accuracy applications.

Product Introduction: The Science Behind Airflow Stabilization

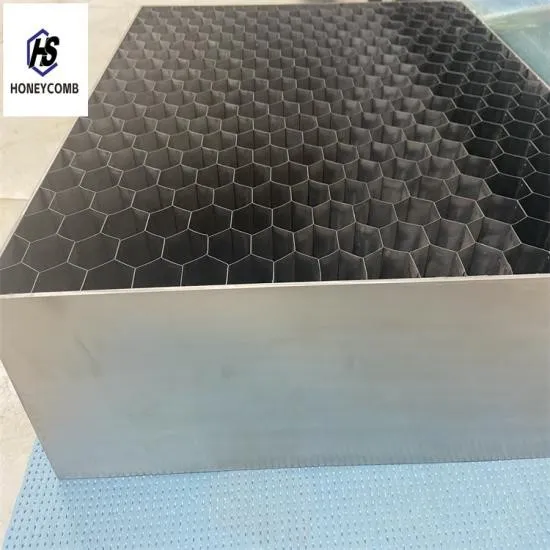

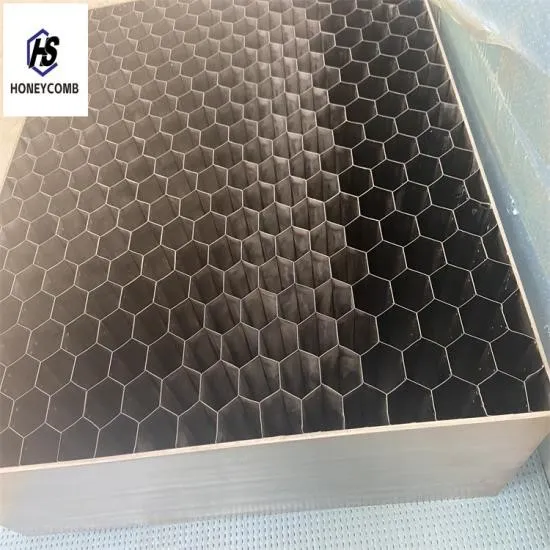

The Honeycomb Air Flow Straightener is a specialized device that transforms turbulent airflow into laminar flow, ensuring precise measurement and analysis in controlled environments. Its design is inspired by the natural structure of honeycombs, which consists of hexagonal cells that create uniform passageways for airflow. This unique configuration minimizes pressure drop while maximizing the open area, typically achieving 95-99% openness.

Originally developed for aerospace and automotive industries, the technology has since expanded to applications in wind tunnel testing, building aerodynamics, and high-speed transportation systems. The straightener's ability to reduce turbulence makes it indispensable in scenarios where accuracy is paramount, such as in the development of aircraft and missiles for aerodynamic efficiency.

Technical Specifications: Engineering Excellence in Detail

The Honeycomb Air Flow Straightener is available in a range of materials, sizes, and configurations to suit diverse industrial needs. Below is a detailed overview of its specifications:

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, ..., 6.0, ..., 8, ..., 10, ..., 12, ..., 20, ..., 30 mm (customizable) |

| Thickness | Customized |

| Shape | Customized (as required) |

| Surface Treatment | Painting, white oxygen, electroless nickel plating, electrophoresis, powder coating, brushing (as required) |

| Package | Wooden cases or as required |

| Certification | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI shielding, air ventilation, cooling, corrosion resistance |

| Application | EMI shielding vent, flow straightener, railways, marine, aviation & aerospace, wind energy, defense, gas seals, communications, medical, and other industries. |

The product's versatility is further enhanced by its ability to be customized in size, shape, and surface treatment. For instance, 304 stainless steel is ideal for high-corrosion environments, while 316L offers superior resistance to harsh chemicals. The Hastelloy X variant is often used in high-temperature applications, such as gas turbine testing.

Applications: From Aerospace to Industrial Innovation

The Honeycomb Air Flow Straightener is a cornerstone of modern aerodynamic testing and industrial ventilation systems. Its applications span multiple sectors, including:

- Aerospace: Used in wind tunnels to simulate airflow around aircraft, missiles, and spacecraft, ensuring optimal design for aerodynamic efficiency and structural integrity.

- Automotive: Essential for testing vehicle aerodynamics, reducing drag, and improving fuel efficiency in high-speed vehicles and electric cars.

- Marine: Applied in ship and submarine design to analyze hydrodynamic resistance and improve propulsion systems.

- Renewable Energy: Utilized in wind turbine testing to optimize blade performance and energy output.

- Medical: Employed in medical equipment for precise airflow control in sterilization chambers and ventilation systems.

One of the most critical applications is in wind tunnel testing, where the straightener ensures that airflow is uniform and free from turbulence. This is vital for accurate data collection in aerodynamic research, as even minor fluctuations can skew results. For example, the Honeycomb Air Flow Straightener is often integrated into wind tunnels used by NASA and other aerospace organizations to simulate flight conditions.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Founded as a leader in the production of high-quality shielding products, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. has established itself as a trusted name in the industry. The company specializes in manufacturing steel honeycomb cores, honeycomb air flow straighteners, and honeycomb seals, all designed to meet rigorous industry standards.

Hengshi's commitment to quality is reflected in its certifications, including ISO9001 and RoHS, which ensure compliance with global safety and environmental regulations. The company's advanced manufacturing techniques, such as spot welding and vacuum brazing, guarantee durability and precision in every product.

With a focus on innovation and customer satisfaction, Hengshi serves a wide range of industries, from aerospace to renewable energy. Its ability to provide customized solutions has made it a preferred partner for organizations seeking reliable and high-performance aerodynamic testing equipment.

Why Choose Hengshi's Honeycomb Air Flow Straightener?

The Honeycomb Air Flow Straightener stands out in the market due to its exceptional performance and adaptability. Key advantages include:

- High Efficiency: The 95-99% open area ensures minimal pressure drop, allowing for energy-efficient airflow management.

- Corrosion Resistance: Available in materials like 316L stainless steel, the product is ideal for harsh environments.

- Customization: Tailored to specific requirements, including size, shape, and surface treatment.

- Compliance: Adheres to international standards such as ISO9001 and RoHS.

These features make the product a preferred choice for industries that demand precision, reliability, and longevity. Whether it's for aerospace testing or industrial ventilation, Hengshi's solution delivers exceptional value.

Industry Standards and Compliance

The Honeycomb Air Flow Straightener is designed to meet the highest standards of performance and safety. While direct references to NIST (National Institute of Standards and Technology) may not be explicitly mentioned in the context, the product's compliance with international standards like ISO9001 and RoHS ensures it aligns with the principles of precision and quality that NIST promotes in measurement and standards development.

As highlighted by NIST, "standards and measurements are fundamental to innovation and economic growth." Hengshi's commitment to these principles is evident in its rigorous testing and adherence to global benchmarks, making its products a reliable choice for industries that rely on precise aerodynamic and environmental control solutions.

Reference: National Institute of Standards and Technology (NIST) - https://www.nist.gov

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025