- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Honeycomb Stainless Steel Air Flow Straightener|Precision Engineering,Aerodynamic Innovation

Product Introduction

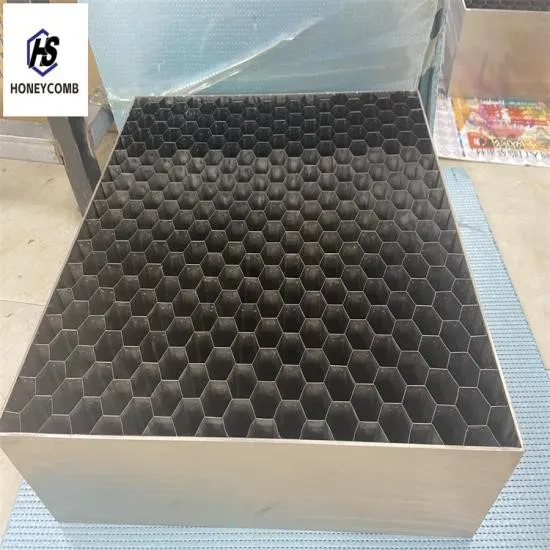

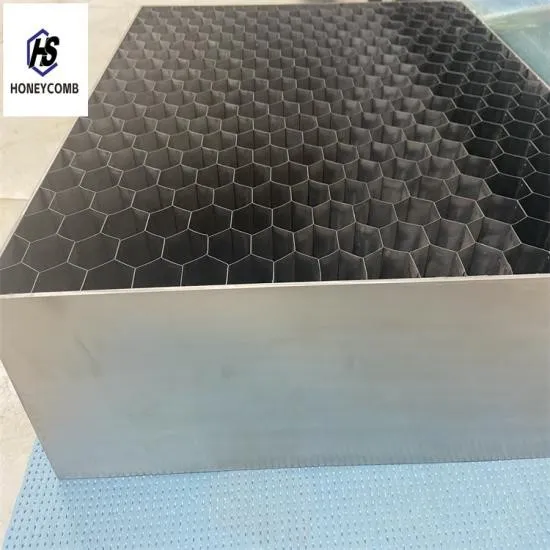

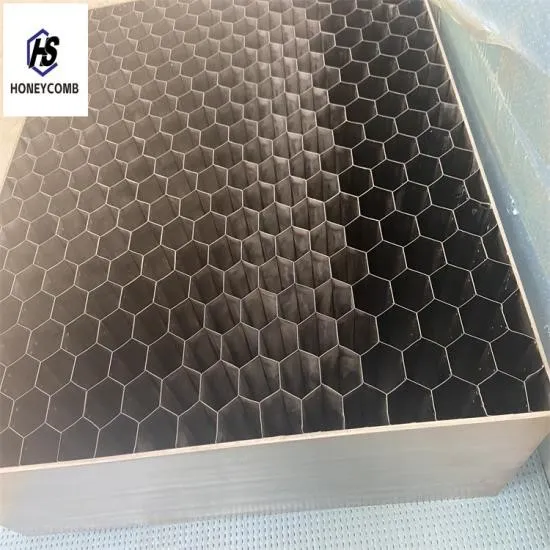

The Honeycomb Stainless Steel Air Flow Straightener represents a pinnacle of precision engineering, designed to stabilize airflow and enhance measurement accuracy in critical applications. This innovative product has been a cornerstone in aerodynamic research and industrial testing for decades. Its unique honeycomb structure, composed of meticulously arranged cells, transforms turbulent airflow into laminar flow, ensuring consistent and reliable results.

The Honeycomb Stainless Steel Air Flow Straightener represents a pinnacle of precision engineering, designed to stabilize airflow and enhance measurement accuracy in critical applications. This innovative product has been a cornerstone in aerodynamic research and industrial testing for decades. Its unique honeycomb structure, composed of meticulously arranged cells, transforms turbulent airflow into laminar flow, ensuring consistent and reliable results.

Originally developed for aerospace and automotive industries, the air flow straightener has evolved to meet the demands of modern engineering. The stainless steel construction offers exceptional durability, corrosion resistance, and thermal stability, making it ideal for environments ranging from high-speed wind tunnels to industrial ventilation systems. Its ability to maintain a high open area (95-99%) while minimizing pressure drop is a testament to its advanced design.

The wind tunnel honeycomb is a critical component in aerodynamic testing. By straightening airflow, it enables engineers to study the effects of air resistance, heat, and pressure on various structures. This technology is widely used in the development of aircraft, missiles, and high-speed trains, as well as in the testing of buildings and marine vessels. Its versatility and reliability have made it an indispensable tool in both academic and industrial settings.

The wind tunnel honeycomb is a critical component in aerodynamic testing. By straightening airflow, it enables engineers to study the effects of air resistance, heat, and pressure on various structures. This technology is widely used in the development of aircraft, missiles, and high-speed trains, as well as in the testing of buildings and marine vessels. Its versatility and reliability have made it an indispensable tool in both academic and industrial settings.

Key Features and Advantages

The Honeycomb Stainless Steel Air Flow Straightener combines advanced materials with cutting-edge engineering to deliver unparalleled performance. One of its standout features is the high shielding effectiveness, which protects sensitive equipment from electromagnetic interference (EMI). This makes it suitable for use in communication systems, medical devices, and defense applications.

Another significant advantage is its anti-corrosion properties. The stainless steel construction resists rust and degradation, even in harsh environments. This ensures long-term reliability and reduces maintenance costs. Additionally, the product offers excellent sound insulation, making it ideal for noise-sensitive applications such as HVAC systems and industrial machinery.

The air flow straightener also excels in ventilation and cooling. Its high open area allows for efficient airflow, while the thin cell walls minimize turbulence. This combination results in a low pressure drop, which is crucial for maintaining energy efficiency in ventilation systems.

The product's adaptability is another key strength. It can be customized to meet specific requirements, including varying foil thicknesses (0.05–0.2 mm), core sizes (0.8–30 mm), and surface treatments such as painting, electroless nickel plating, and powder coating. This flexibility ensures that the wind tunnel honeycomb can be tailored to a wide range of applications, from aerospace to renewable energy systems.

The product's adaptability is another key strength. It can be customized to meet specific requirements, including varying foil thicknesses (0.05–0.2 mm), core sizes (0.8–30 mm), and surface treatments such as painting, electroless nickel plating, and powder coating. This flexibility ensures that the wind tunnel honeycomb can be tailored to a wide range of applications, from aerospace to renewable energy systems.

Technical Specifications

| Material | Carton steel, 304 stainless steel, 316L, Hastelloy X, Haynes 214, Aluminum, Brass, Copper, etc. |

|---|---|

| Foil Thickness | 0.05, 0.07, 0.076, 0.1, 0.13, 0.15, 0.2 mm |

| Core Size | 0.8, 1.0, 1.2, 1.6, 2.0, 2.2, 2.4, 2.5, 3.0, 3.2, 4.2, 4.8, 5.0, 5.2, 6.0, 8, 10, 12, 20, 30 mm (as required) |

| Thickness | Customized |

| Shape | As required |

| Surface Treatment | Painting, white oxygen, Electroless Nickel plating, electrophoresis, powder coating, Brush (as required) |

| Package | Wooden cases; or as required |

| Certificate | ISO9001, RoHS |

| Welding Technology | Spot welding, vacuum brazing |

| Function | EMI Shielding, Air Ventilation, Cooling, Corrosion Resistance |

| Application | EMI shielding vent, flow straightener, railways, Marine, aviation & aerospace, wind energy, defence, gas seals, communications, medical and other industries |

Applications in Aerodynamic Research and Industry

The Honeycomb Stainless Steel Air Flow Straightener plays a vital role in aerodynamic research, where precise airflow control is essential. Wind tunnels, which simulate real-world airflow conditions, rely on this technology to study the performance of aircraft, missiles, and other vehicles. By eliminating turbulence, the wind tunnel honeycomb ensures that test results are accurate and repeatable.

In the automotive industry, the product is used to test vehicle aerodynamics, reducing drag and improving fuel efficiency. For aerospace applications, it helps engineers analyze the effects of high-speed airflow on aircraft structures, ensuring safety and performance. The air flow straightener is also critical in the development of high-speed trains and marine vessels, where minimizing resistance is key to optimizing speed and energy consumption.

Beyond transportation, the product is used in the construction of buildings and infrastructure. By simulating wind loads, engineers can design structures that withstand extreme weather conditions. In the renewable energy sector, the Honeycomb Stainless Steel Air Flow Straightener is employed in wind turbine testing, ensuring optimal performance and longevity.

Beyond transportation, the product is used in the construction of buildings and infrastructure. By simulating wind loads, engineers can design structures that withstand extreme weather conditions. In the renewable energy sector, the Honeycomb Stainless Steel Air Flow Straightener is employed in wind turbine testing, ensuring optimal performance and longevity.

The wind tunnel honeycomb also finds applications in defense and aerospace, where it is used to test missile systems and other high-speed projectiles. Its ability to maintain laminar flow under extreme conditions makes it an essential tool for ensuring the accuracy and reliability of these critical systems.

Company Background: Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd.

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. is a leading manufacturer of high-quality shielding products, including ventilation panels, steel honeycomb cores, and air flow straighteners. With a commitment to innovation and excellence, the company has established itself as a trusted supplier in the global market.

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. is a leading manufacturer of high-quality shielding products, including ventilation panels, steel honeycomb cores, and air flow straighteners. With a commitment to innovation and excellence, the company has established itself as a trusted supplier in the global market.

Founded on the principles of precision engineering and customer-centric solutions, Hengshi specializes in producing products that meet the stringent requirements of various industries. Their wind tunnel honeycomb is a testament to their expertise, offering superior performance and durability. The company's ISO9001 and RoHS certifications underscore their dedication to quality and environmental responsibility.

Hengshi's product range extends beyond air flow straighteners, encompassing EMI shielding solutions, corrosion-resistant components, and custom-engineered systems. Their ability to provide tailored solutions ensures that clients receive products that perfectly match their specific needs. This flexibility, combined with their state-of-the-art manufacturing capabilities, positions Hengshi as a leader in the industry.

With a focus on continuous improvement and technological advancement, Hengshi remains at the forefront of innovation. Their commitment to research and development ensures that their products stay ahead of industry trends, providing customers with cutting-edge solutions that drive efficiency and performance.

The Role of Precision in Aerodynamic Innovation

As highlighted by the National Institute of Standards and Technology (NIST), precision engineering is critical in advancing technology and ensuring the reliability of scientific instruments. According to NIST, "measurements and research fuel innovation and improve the quality of life for all Americans" (NIST, 2025). The Honeycomb Stainless Steel Air Flow Straightener exemplifies this principle, as its precise design enables accurate aerodynamic testing and analysis.

NIST's work in developing standards for measurement and testing underscores the importance of tools like the air flow straightener. These tools are essential for ensuring that experiments and simulations are conducted under controlled conditions, leading to reliable results. The wind tunnel honeycomb plays a vital role in this process, providing the stability needed for high-accuracy measurements.

By adhering to NIST's standards, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. ensures that their products meet the highest levels of quality and performance. This commitment to precision not only benefits their customers but also contributes to the broader goals of technological advancement and scientific progress.

Conclusion

The Honeycomb Stainless Steel Air Flow Straightener is a remarkable example of precision engineering, combining advanced materials with innovative design to deliver exceptional performance. Its ability to stabilize airflow and enhance measurement accuracy makes it an indispensable tool in aerodynamic research, industrial testing, and various other applications.

With a wide range of technical specifications, customizable options, and a commitment to quality, Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. continues to set the standard for excellence in the industry. Their products not only meet the demands of modern engineering but also contribute to the advancement of technology and scientific innovation.

As the need for precision and reliability grows, the air flow straightener will remain a critical component in the development of cutting-edge solutions. Whether in aerospace, automotive, or renewable energy, this technology continues to drive progress and shape the future of engineering.

References

NIST. (2025). National Institute of Standards and Technology. Retrieved from https://www.nist.gov/

Hengshi (Langfang) Precision Machinery Manufacturing Co., Ltd. (n.d.). Honeycomb Stainless Steel Air Flow Straightener. Retrieved from https://www.hshihoneycomb.com/honeycomb-stainless-steel-air-flo.html

Products categories

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025