- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jan . 09, 2025 14:06

Back to list

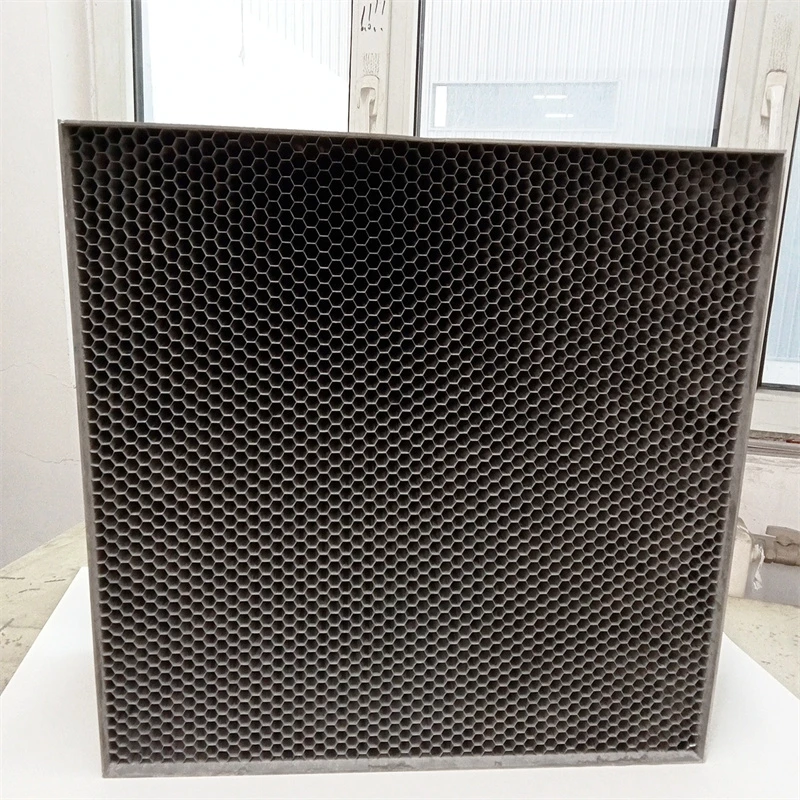

honeycomb plate

Honeycomb plates, an engineering marvel, have revolutionized numerous industries with their unique structure and beneficial properties. These plates, characterized by a honeycomb-like core, offer an unparalleled combination of light weight and high strength, making them an ideal choice for various applications. As an experienced engineer and SEO specialist, I delve into the exceptional features and applications of honeycomb plates, underlining their role as a cornerstone in modern manufacturing and design.

The furniture industry has also embraced honeycomb plates for their modern aesthetics and practical benefits. Lightweight and sturdy furniture pieces are highly valued for both residential and commercial use, offering ease of transport and installation. Furthermore, the eco-friendly nature of honeycomb plates—thanks to their efficient use of materials—aligns with growing consumer demand for sustainable products. From an expert perspective, the production of honeycomb plates involves advanced technology and precise manufacturing processes. Engineers and manufacturers ensure that each plate meets stringent quality standards to maintain their reliable performance across all applications. This attention to detail fosters trust and confidence in industries that rely heavily on these materials. Honeycomb plates are not just engineering components; they stand as a testament to how biomimicry can lead to sustainable and efficient solutions in technology and design. Their adaptability, coupled with outstanding mechanical properties, allows them to remain at the forefront of innovative material solutions across various sectors. For businesses and consumers alike, choosing products made from honeycomb plates signifies a step towards advancing technology without compromising environmental standards. As honeycomb plate technology continues to evolve, its potential applications expand, always promising new innovations in product design and functionality. Its role in shaping the future of materials science is undeniable, heralding a new era of development in industries worldwide.

The furniture industry has also embraced honeycomb plates for their modern aesthetics and practical benefits. Lightweight and sturdy furniture pieces are highly valued for both residential and commercial use, offering ease of transport and installation. Furthermore, the eco-friendly nature of honeycomb plates—thanks to their efficient use of materials—aligns with growing consumer demand for sustainable products. From an expert perspective, the production of honeycomb plates involves advanced technology and precise manufacturing processes. Engineers and manufacturers ensure that each plate meets stringent quality standards to maintain their reliable performance across all applications. This attention to detail fosters trust and confidence in industries that rely heavily on these materials. Honeycomb plates are not just engineering components; they stand as a testament to how biomimicry can lead to sustainable and efficient solutions in technology and design. Their adaptability, coupled with outstanding mechanical properties, allows them to remain at the forefront of innovative material solutions across various sectors. For businesses and consumers alike, choosing products made from honeycomb plates signifies a step towards advancing technology without compromising environmental standards. As honeycomb plate technology continues to evolve, its potential applications expand, always promising new innovations in product design and functionality. Its role in shaping the future of materials science is undeniable, heralding a new era of development in industries worldwide.

Prev:

Products categories

Latest news

-

Why Vented Aluminum Honeycomb Is Leading the Way in Shielding and Ventilation SolutionsNewsJul.18,2025

-

Why Stainless Steel Honeycomb Panel is the Ultimate Choice for High-Tech Shielding and ProtectionNewsJul.18,2025

-

Why Honeycomb Strips Are Revolutionizing High-Speed Sealing SolutionsNewsJul.18,2025

-

Shielded Glass Innovation Powers the Future of Electromagnetic ProtectionNewsJul.18,2025

-

Precision Starts Here: Revolutionizing Airflow Control with Honeycomb Wind Tunnel SolutionsNewsJul.18,2025

-

Elevate Industrial Performance with Precision-Engineered Steel Honeycomb Core SolutionsNewsJul.18,2025

-

Vented Aluminum Honeycomb: A Smart Shield for Airflow and EMI ControlNewsJul.11,2025